Pulp Molding: A Paper Alternative to Plastic

In an era where environmental concerns are at the forefront of consumer choices, industries are increasingly seeking sustainable alternatives to traditional plastic packaging. Pulp molding has emerged as a compelling solution that utilizes recycled paper pulp to create eco-friendly packaging. This article delves into the advantages of pulp molding and its effectiveness as a viable alternative to plastic.

Understanding Pulp Molding

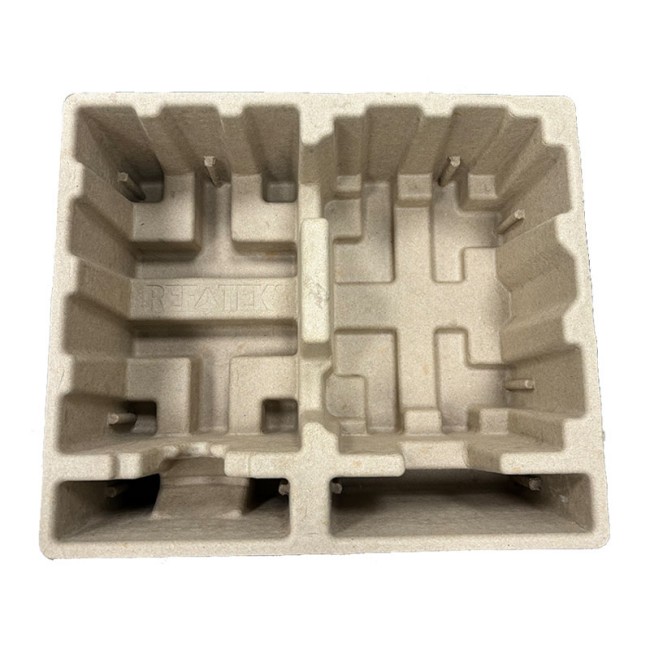

Pulp molding is an innovative manufacturing process that converts raw paper pulp into a diverse range of molded products. The process begins with mixing recycled paper with water to create a slurry, which is then shaped using molds. Once dried, the pulp forms a robust and lightweight packaging solution that is suitable for various applications, including food containers, electronics packaging, and protective inserts.

Advantages of Molded Pulp Packaging

-

Sustainability: One of the most compelling benefits of molded pulp packaging is its commitment to sustainability. By utilizing recycled materials, pulp molding significantly reduces waste and minimizes the demand for new plastic production. Unlike plastic, which can take centuries to decompose, molded pulp products are biodegradable and compostable, making them an environmentally responsible choice.

-

Customizability: Pulp molding companies offer extensive customization options to cater to specific packaging needs. This includes the creation of unique shapes, sizes, and textures that enhance product presentation. Brands can also incorporate logos and branding elements into the packaging, effectively turning their packaging into a marketing tool that resonates with eco-conscious consumers.

-

Superior Protection: Molded fiber packing provides exceptional cushioning and protection for products during transit. The molded pulp is designed to absorb shock and resist impact, ensuring that fragile items reach their destination safely. This protective feature makes it particularly advantageous for packaging electronics, glassware, and other delicate products.

-

Cost-Effectiveness: While the initial investment in paper pulp molding may be higher than that of traditional plastic options, the long-term savings can be substantial. By using recycled materials, companies can lower their raw material costs. Additionally, the lightweight nature of molded pulp can lead to reduced shipping costs, making it an economically viable packaging solution.

Industry Adoption and Growth

As awareness of the environmental impact of plastic packaging continues to grow, an increasing number of companies are turning to molded pulp packaging as an alternative. Major brands across diverse sectors—such as food and beverage, electronics, and cosmetics—are embracing this sustainable solution. This rising demand has prompted a surge in the number of pulp molding companies entering the market, fostering innovation and competition in the industry.

Conclusion:

Pulp molding represents a significant advancement in the quest to reduce plastic waste and promote sustainability in packaging. With its biodegradable properties, customization options, and superior protective qualities, molded pulp packaging stands out as a practical and eco-friendly alternative to traditional plastic. As industries continue to prioritize sustainability, the adoption of paper pulp molding is set to increase, paving the way for a greener future. By choosing molded fiber packing, companies can not only meet their packaging needs effectively but also make a positive impact on the environment, contributing to a more sustainable world.